How is Chocolate Made from Cacao?

Everyone loves chocolate...

But not everyone knows where it comes from. To hear the story of how cacao is harvested, transported, and transformed is to know the wonder of chocolate — its science, flavor, and art.

Lake Champlain Chocolates is a chocolatier — crafting finished chocolate into confections and bars, as opposed to a chocolate maker that sources raw cacao beans to roast, winnow, grind, and mould into single-origin bars. Of the chocolate in our finished products, 100% is fair trade certified, sourced primarily from the Dominican Republic.

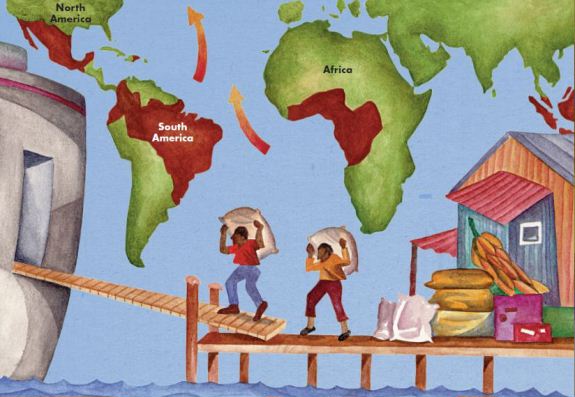

But no matter the origin of the cocoa beans, whether it’s a blend of Latin American and African cacao, or a single-origin chocolate bar, the process for making chocolate is essentially the same. And it starts with the tree, pod, and bean . . .

Making Chocolate — Step by Step:

1. Cacao Cultivation:

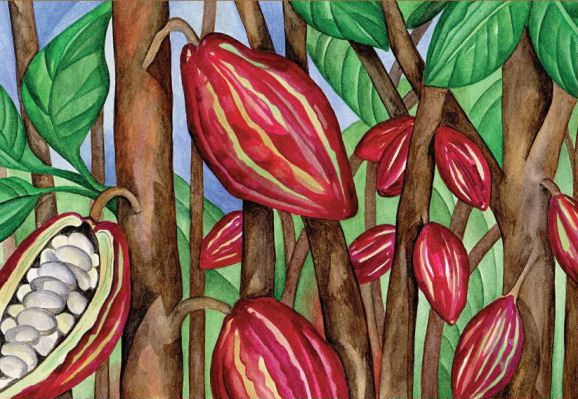

Chocolate begins with the cacao tree (Theobroma cacao), which grows within 20° north and south of the Equator and thrives on a mix of hot temperatures, rain, and shade.

Each tree bears oval fruits, or pods, which are about 5–12 inches long. Each pod contains 30–50 seeds, and it’s these seeds the world knows as cacao (or cocoa) beans.

What is the difference between cocoa and cacao? The tree, pod, and bean/seed are typically referred to as “cacao,” while the word “cocoa” is reserved for the bean after it has been fermented, dried, and roasted.

2. Harvesting:

Cacao pods are ripe when they turn a vibrant yellow/orange color. Hanging from the trunk and largest branches on small stems, the ripening pods are typically harvested twice per year, though they can be harvested continually.

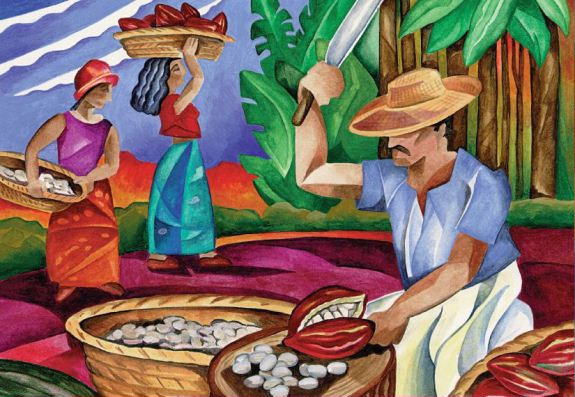

After being chopped off, the pods are opened and their seeds are removed. Each seed is about the size of an olive. The seeds (or “beans”) grow in five columns surrounded by a white pulp or pith.

In Latin America this pulp, called baba, was used to make a fermented cacao wine as early as 3,000 years ago.

3. Fermentation:

Beans are cleaned by hand, with the baba left on to help develop flavor. Exposed to light, the cream-colored beans turn a purplish color.

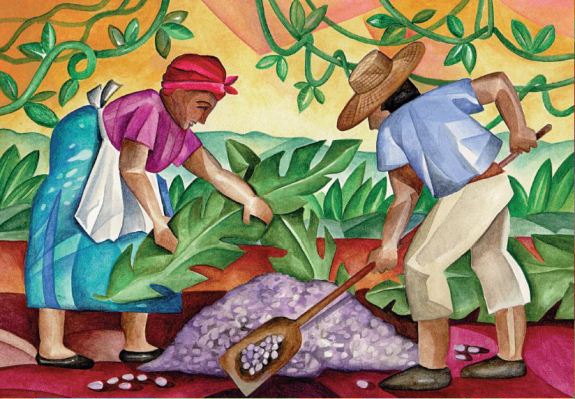

Then they’re ready for fermentation via one of two ways: the “heap method” is popular in Africa, where beans are heaped in piles on the ground; and in Latin America, a system of cascading boxes is favored.

In both methods, beans are covered with banana leaves. During the 2–9 days of fermentation, beans begin to take on color and some of the flavors you would recognize as “chocolate.”

4. Drying & Shipping:

Fermented beans must be carefully dried. They are placed either on wooden boards or bamboo mats for anywhere from 7 to 14 days under the hot sun, and are continually raked and turned over for consistent drying.

Once dried, the beans are graded, packed into sacks, bundled, and checked for quality. They are then shipped and traded on the international market.

Or, in the case of direct trade (for craft, bean-to-bar chocolates), the beans are exported directly to the chocolate maker.

5. Preparing Cocoa Mass (a.k.a. “Cocoa Liquor”):

Once received by the processor, beans may be blended with other origins and estates for desired characteristics (or kept separate as “single-origin chocolate”).

Beans are cleaned, then roasted at low temperatures to develop flavor. Shells are separated from the nibs (the “meat” of the bean) by a process called winnowing.

Nibs are finely ground into cocoa mass (a.k.a. cocoa liquor), which is solid at room temperature. Placed under extremely high pressure, this paste yields two products: cocoa powder and cocoa butter.

6. Producing Chocolate:

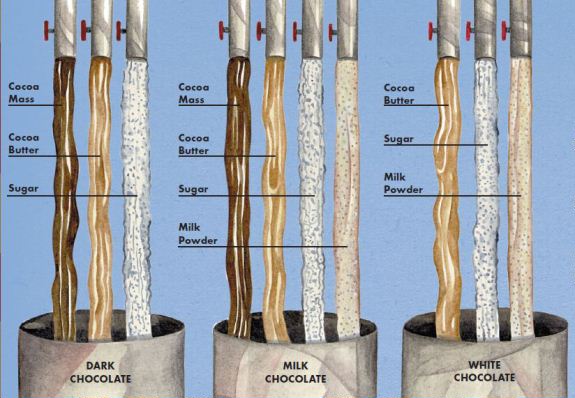

Or, cocoa mass can simply be combined with more cocoa butter and sweetener to make chocolate. The first steps are to mix, grind, and knead the various raw ingredients into a paste.

The ingredients used are dependent on the type of chocolate being made. Dark chocolate requires only cocoa mass, cocoa butter, and sugar. Adding milk powder makes milk chocolate.

White chocolate is made with cocoa butter, sugar, and milk powder (but no cocoa mass/liquor). Because it contains no cocoa mass, some do not consider it a true chocolate.

7. Conching:

“Conching” is a careful process of rolling, kneading, heating, and aeration. A conche is a large agitator that stirs and smooths the mixture under heat.

This is an important step in the process of producing consistent, pure, and delicious gourmet chocolate — and it is here that the final aroma and flavor are defined.

At this point, soy lecithin and cocoa butter may be added for required fluidity. Chocolate is then refined until smooth (and the longer a chocolate is conched, the smoother it will be).

8. Tempering & Moulding:

The chocolate is now finished and ready for final processing. To be delivered to a chocolatier, it must first be put into blocks or drops (also called “pistoles”).

This method requires “tempering” — whereby chocolate is slowly brought to a certain temperature. Tempering chocolate is something any aspiring baker or chocolate maker can try at home.

During the tempering process, the cocoa butter reaches its most stable form; this gives well-tempered chocolate its “snap,” shiny surface, and smoothness. Proper tempering also helps prevent bloomed chocolate.

9. Never-Ending Creativity:

Of course, “finished” chocolate doesn’t always stay in this form . . .

Around the world, chocolatiers, bakers, chefs, and pastry experts use this highly versatile, delicious food in countless applications and preparations, from simple to elaborate.

And cooking with chocolate is a joy for everyone, not just the pros — so we hope you’ll take a look around the recipes portion of our website, and try your hand at one of our recommended dishes!